Mechanical characteristic evaluation

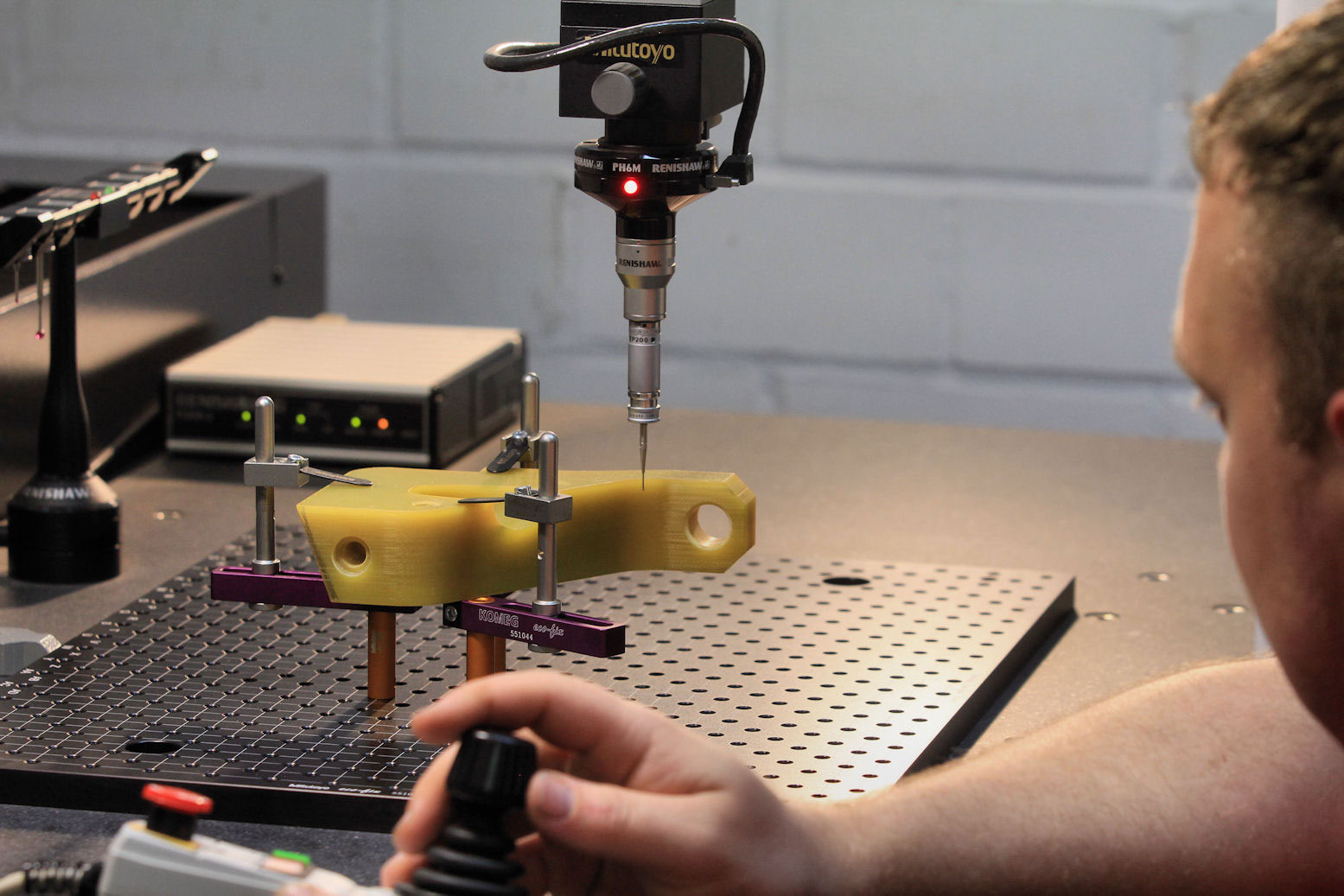

For the determination of the mechanical properties such as

- Bending strength

- Tensile strength

- Compressive strength

- Shear strength

- Gap load

a 20kN universal testing machine is available, which is used for characterization and monitoring of our own materials as well as for materials of customers and for interlaboratory tests. The test arrangements correspond to the valid DIN and/or VDE - standards. The determination of the above-mentioned characteristic values can be carried out in a temperature range between -60 and 250°C. Special arrangements, such as peeling tests using the drum peeling method, round off the range of test procedures.

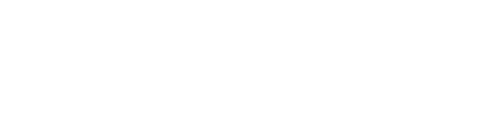

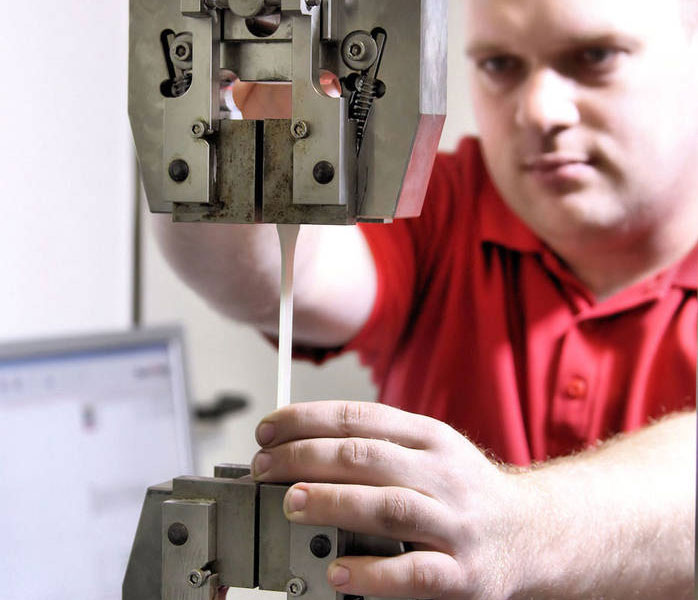

Coordinate measurement station

With the 3D coordinate measuring station, machined parts of any geometry can be measured in 3 axes. The maximum external dimension of the parts is 400 x 300 x 200 mm, the achievable accuracy up to 0.001 mm. A TARGET / ACTUAL protocol is created about the measurement, which is supplied to the customer on request. The measurement of machined parts is also available as an external service.

Tribological properties

Our slide bearing materials offer designers in mechanical and plant engineering many possibilities for use in sliding solutions under extreme operating conditions with high reliability as well as freedom from maintenance. A wide range of plain bearing concepts can be realized with these self-lubricating high-performance materials, which are adjusted by modifications for special applications. This applies in particular to slow-running systems.

State-of-the-art testing technology ensures accurate knowledge and settings of tribological properties such as wear rate, coefficient of friction and temperature development of our materials. This technology makes it possible to simulate a wide variety of operating conditions. By selecting appropriate additives, specific windows of the coefficient of friction can be set, so that these plastics can also be used in clutch and brake applications.