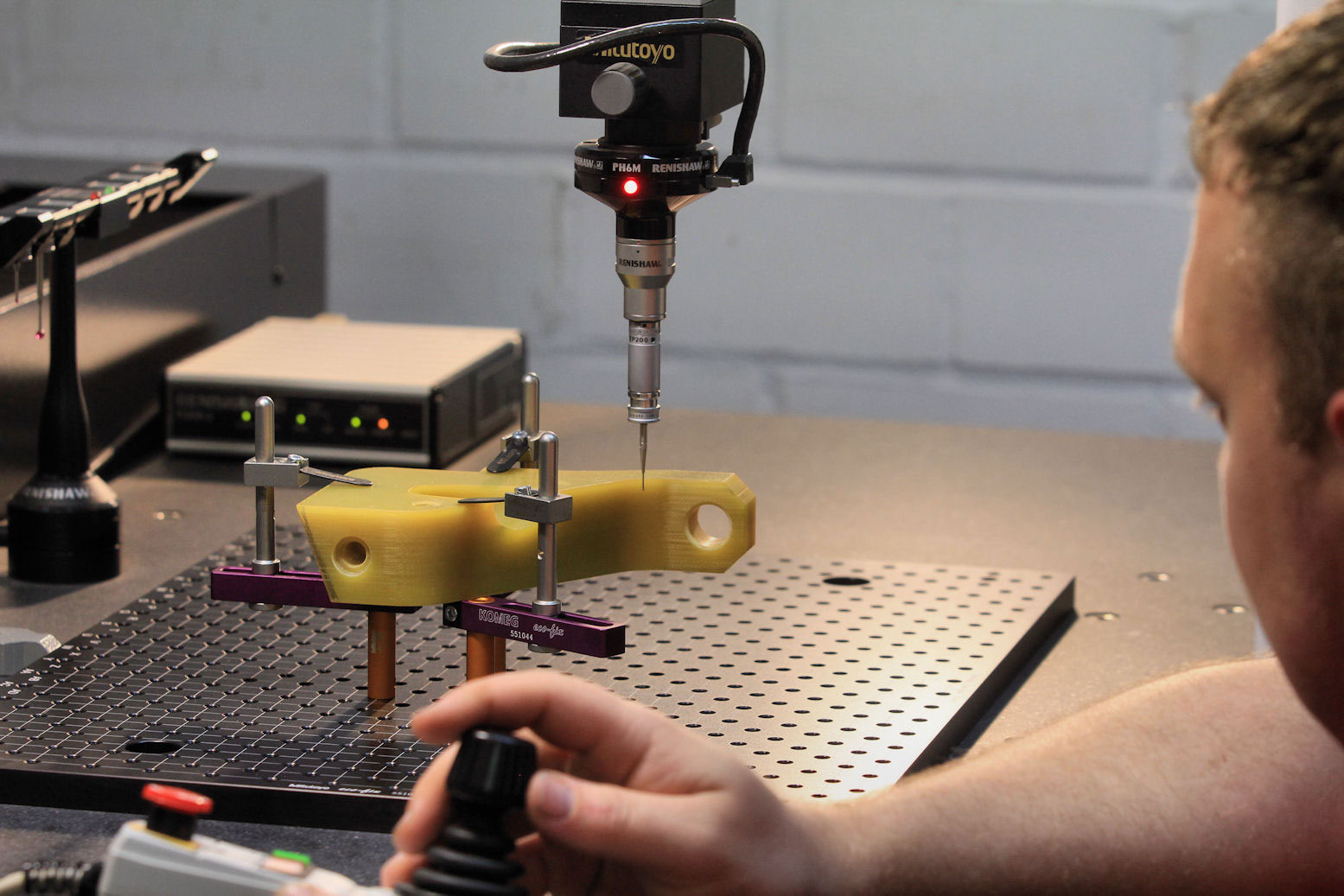

Our overall concept is impressive. This is evidenced by internal customer audits, but of course also by industry-typical basic requirements such as certification in accordance with DIN EN ISO 9001, which we have had introduced and regularly monitored since 1999. This includes the annual calibration of all measuring and testing equipment as well as the annual software update of our measuring equipment management.

Continuous tracking of our products and manufacturing processes back to the raw material suppliers make our production process reliable and ensure a consistent level of quality, which are digitally archived for each order through managed documents before - during and after production.

It is essential that in our industry there are clear guidelines against which our organization and the service it provides are evaluated and categorized. DIN EN ISO 9001 was the prerequisite for building a strategic customer base. Through joint material developments as well as perennial material release procedures, we have become a preferred supplier to a large number of customers in the industries

- Machinery - and plant engineering

- Transportation

- Packaging industry

- as well as power generation

approved as a supplier. Among them are today well-known companies for which we are established as a strategic supplier. The positioning in the supplier network ranges from preferred supplier to first tier supplier for producing OEMs.

Numerous materials meet customer-specific standards / properties. You can get an overview here.

![[Translate to English:] Airbus Airbus](/fileadmin/files/misc/logos_airbus.jpg)

![[Translate to English:] Alstom Alstom](/fileadmin/files/misc/logos_alstom.jpg)

![[Translate to English:] Bobst Bobst](/fileadmin/files/misc/logos_bobst.jpg)

![[Translate to English:] Bosch Bosch](/fileadmin/files/misc/logos_bosch.jpg)

![[Translate to English:] FEAG FEAG](/fileadmin/files/misc/logos_feag.jpg)

![[Translate to English:] Siemens Siemens](/fileadmin/files/misc/logos_siemens.jpg)

![[Translate to English:] Valeo Valeo](/fileadmin/files/misc/logos_valeo.jpg)